DERATECH is committed to providing high-quality sheet metal processing equipment and intelligent manufacturing solutions, custom-tailored according to customer needs. Based on sheet metal processing equipment, the automated & flexible manufacturing cell and system are equipped with an automatic material stocker, automatic loading and unloading devices, as well as other auxiliary devices. These are automatically controlled by the CNC system, greatly enhancing the automation of the sheet metal processing process and improving production efficiency.

-

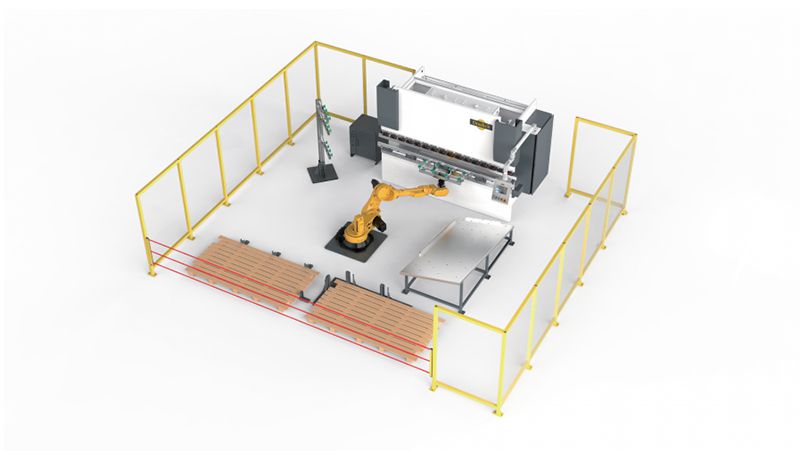

- Stationary Robot Bending Cell

RBC Series

Stationary robot bending cell integrates multi-joint industrial robots with CNC bending machines to achieve automatic gripping, centering, bending, and stacking of sheet metal, thereby enabling automated bending. Depending on the weight, size, and bending requirements of the workpiece, suitable models of bending machines and robots can be chosen. Additionally, customized auxiliary devices can be designed to fulfill specific requirements. View Product

-

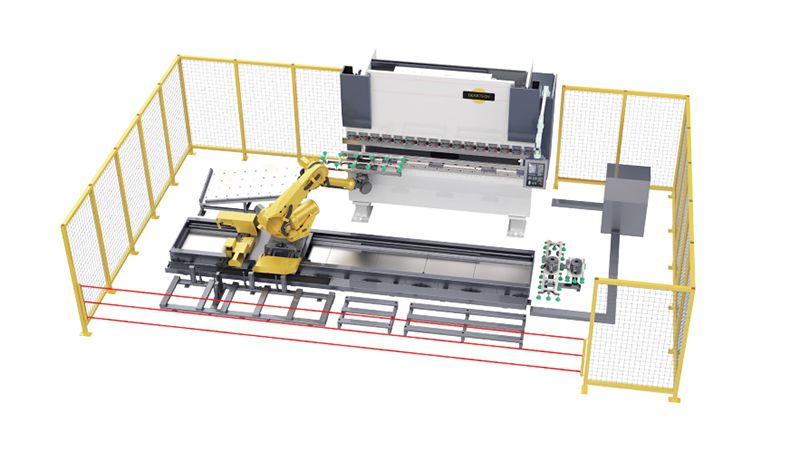

- Mobile Robot Bending Cell

RBC Series

Mobile robot bending cell seamlessly integrates CNC bending machines and robots using a PLC motion control system, enabling the automatic gripping, centering, bending, and stacking of sheet metal. This advanced system significantly reduces manual labor intensity while effectively improving production efficiency, resulting in substantial cost savings. Customized bending unit solutions are available based on the specific bending requirements of customer workpieces, ensuring maximum customer satisfaction. View Product

-

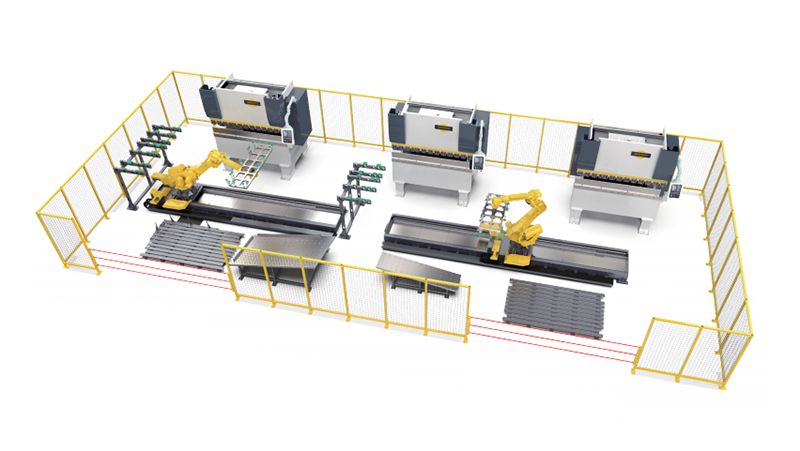

- Sheet Metal Bending Flexible Manufacturing System

FMS Series

FMS series sheet metal bending flexible manufacturing system consists of multiple CNC bending machines and robots working in coordination to achieve automated bending of complex products. This system enables the entire bending process of a product to be completed in one step, reducing intermediary steps, improving production efficiency, saving production space, and facilitating lean manufacturing. View Product

-

- Coil-Fed Laser Blanking Line

Super S-F Series

Super S-F series Coil-fed laser blanking machine, innovatively developed by DERATECH, is an automated flexible manufacturing line that integrates functions of uncoiling, feeding, cutting, and discharging. It has broad applications in industries that require continuous production of various metal sheet products, such as metal doors and windows, HVAC equipment, chassis cabinets, shelves, and filing cabinets. View Product

-

- Flexible Laser Cutting Cell

FMC Series

FMC series flexible laser cutting machine consists of a CNC laser cutting machine, an automatic stocker, and a loading/unloading device. It automatically completes the picking up, loading, cutting, and unloading of sheet metal, enabling batch continuous processing of various specifications of sheet metal. View Product

-

- Flexible Laser Cutting Cell with Automatic Loading & Unloading

FMC Series

FMC series flexible laser cutting cell can automatically load, cut, and unload sheet metal, significantly improving processing efficiency, reducing labor intensity, and enhancing processing safety. View Product

-

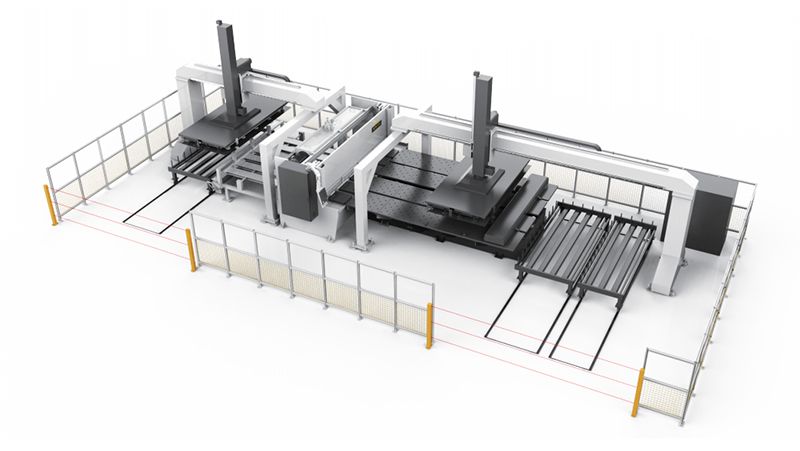

- Laser Cutting Flexible Manufacturing System

FMS Series

FMS series laser cutting flexible manufacturing system comprises a single-column multi-layer material stocker, automatic loading/unloading devices, and three laser cutting machines. This system can automatically complete a series of uninterrupted production processes from sheet metal storage to automatic loading, cutting, and unloading. View Product

-

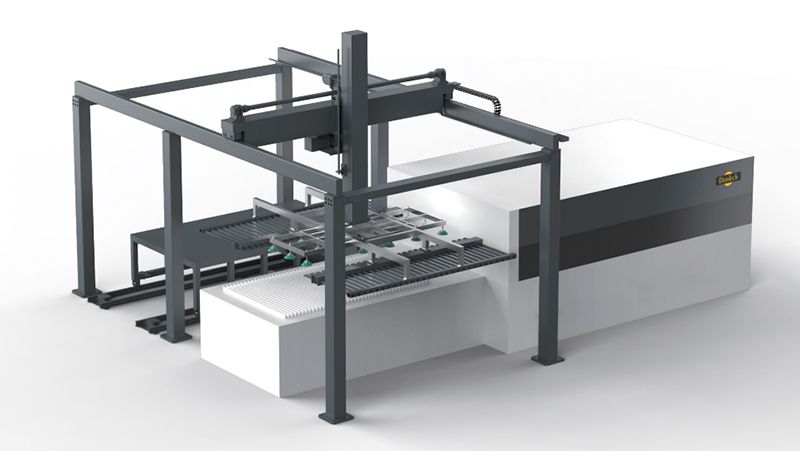

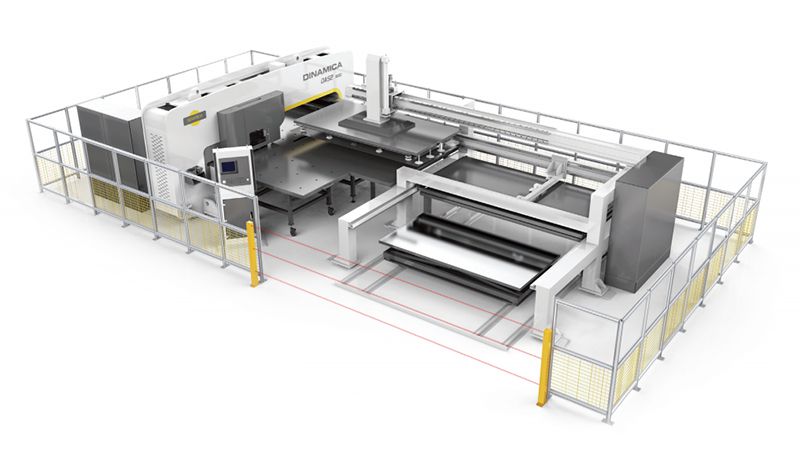

- Automatic Stamping Flexible Manufacturing Cell

FMC Series

Automatic stamping flexible manufacturing cell integrates CNC punch press and automatic loading/unloading devices through a PLC motion control system. It enables automatic feeding, stamping, and automatic stacking of sheet metal, effectively reducing manual labor intensity and significantly improving production efficiency, resulting in substantial cost savings. View Product

-

- Sheet Metal Shearing Flexible Manufacturing System

FMS Series

Sheet metal shearing flexible manufacturing system aims to improve the level of automation and flexibility in the loading and unloading process of a shearing machine. The shearing cell comprises several components, including an automatic feeding device that picks up raw material and transfers it to the front feeding device, where the shearing machine completes the cutting process. Subsequently, the cut sheets are discharged and stacked by an automatic stacking device. View Product