Future Series fiber laser cutting machine is a new generation of high-speed fiber laser cutter launched by DEARTECH for the high-end sheet metal market. Currently, our laser cutting machines have entered the mass production stage, and customer inventory has been quite substantial. The fiber laser cutter plays a crucial role in industries such as including aluminum curtain walls, stainless steel processing, commercial kitchenware, chassis, cabinets, elevators, containers, and multi-story garages.

-

- CNC Fiber Laser Cutting Machine

Future A Series

Future A series CNC fiber laser cutting machine is a high-tech metal cutting equipment that integrates laser technology, CNC technology, and precision mechanical technology. The cutter features a top-notch fiber laser with excellent electro-optical conversion efficiency, providing consistent power and optimal beam quality. View Product

-

- CNC Fiber Laser Cutting Machine

Future H Series

Future H series CNC fiber laser cutting machine is designed for high-power cutting applications, enabling ultra-high-speed cutting of thin sheets and efficient processing of medium-thick plates. This metal cutting machine excels in the processing of various metal materials. View Product

-

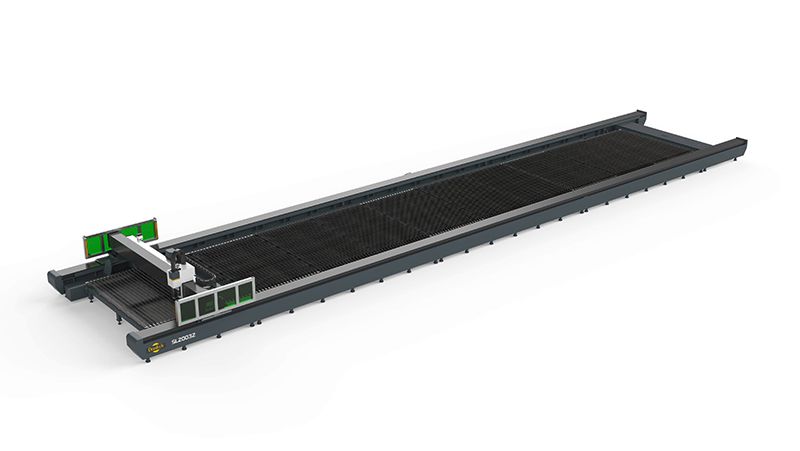

- CNC Large Table Fiber Laser Cutting Machine

Future L Series

Future L series CNC fiber laser cutting machine is custom-designed for cutting large-sized sheet metal according to customer requirement. The metal cutting machine features a split-joint gantry structure with high-strength welded steel beams, ensuring both processing precision and efficiency, as well as energy efficiency, environmental friendliness, and low operating costs. View Product

-

- CNC Single Table Fiber Laser Cutting Machine

Future S Series

Future S series CNC single table fiber laser cutting machine comes with a compact and simple structure. In comparison to large table laser equipment with exchange worktables, it offers significant advantages in terms of size and space, providing a "small, fast, and flexible" processing approach. View Product

-

- CNC Fiber Laser Tube Cutting Machine

TE Series

TE series CNC fiber laser tube cutting machine is a cost-effective laser processing equipment that caters to the specific demands of the sheet metal processing industry for pipe processing. Unlike traditional cutting methods, laser cutting provides excellent flexibility without the need for tooling, thereby saving significant time in new product development. It boasts fast cutting speed, high precision, and the ability to achieve precise cutting of various complex and irregular shapes that are difficult to achieve using conventional methods, such as hole cutting, bevel cutting and intersecting lines. View Product

What is a fiber laser cutting machine?

What is a fiber laser cutting machine?

A fiber laser cutting machine is a type of sheet metal machinery that utilizes laser technology for material cutting. It uses a laser beam to focus high-energy light on a small area to melt, vaporize, or blow away the material, thereby achieving cutting.

What types of lasers do metal fabricators use for cutting steel?

What types of lasers do metal fabricators use for cutting steel?

CO2 and fiber lasers are the most commonly used cutting lasers.

Is fiber laser better than CO2 cutting?

Is fiber laser better than CO2 cutting?

The wavelength of the fiber laser is shorter than that of the CO2 laser, meaning that the cutting power is concentrated in a smaller area. Higher energy density can achieve faster cutting at the same laser power, resulting in a higher number of parts processed per hour.

What are the applications of fiber laser cutting machines?

What are the applications of fiber laser cutting machines?

Fiber laser cutting equipment is widely used in automotive manufacturing, kitchenware industry, sheet metal processing, advertising industry, mechanical manufacturing, and other fields. It is also flexible in processing applications such as cabinets, elevator manufacturing, and fitness equipment.

What materials can a fiber laser cut?

What materials can a fiber laser cut?

Fiber lasers are well-suited for cutting stainless steel, copper, aluminum, carbon steel, alloy steel, and other black and non-ferrous metals.

What safety measures are there when using a laser cutter?

What safety measures are there when using a laser cutter?

Proper ventilation and personal protective equipment (PPE) such as safety glasses and gloves should prevent harmful smoke and potential laser exposure. Operators should also receive appropriate training and comply with established safety protocols.

How to choose a right laser cutting machine?

How to choose a right laser cutting machine?

Choosing the right laser cutting machine requires consideration of multiple factors, including application requirements, material types, cutting thickness, precision requirements, production volume, and budget, etc. Please contact us if necessary, we will recommend suitable equipment for you.