We will gladly assist you in making the right decision to achieve your business goals

The automotive repair & maintenance equipment industry often uses large workpieces similar to channel steel. These types of workpieces require 3-5 people to complete tasks such as loading, bending, and stacking. Additionally, the size and dimensional specifications of the finished products vary greatly, making precision control difficult. The customer wanted to update their sheet metal processing machines to reduce labor costs, improve product accuracy, and achieve quick response times.

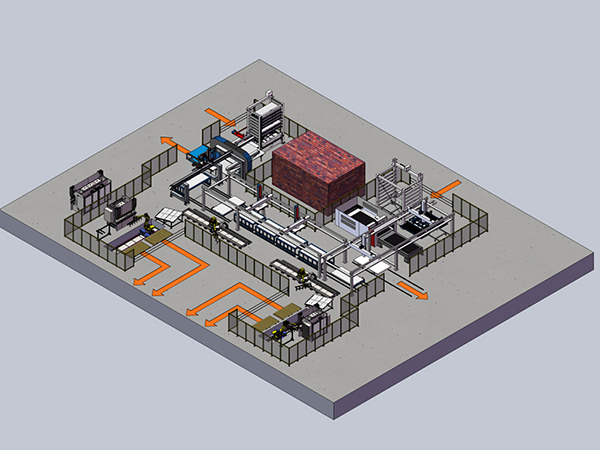

Through detailed analysis of the workpieces and reasonable planning and design, DERATECH tailored a robotic bending cell for EAE Company. This unit consists of a CNC press brake, a FANUC six-axis robot, and a set of horizontal 7th-axis.

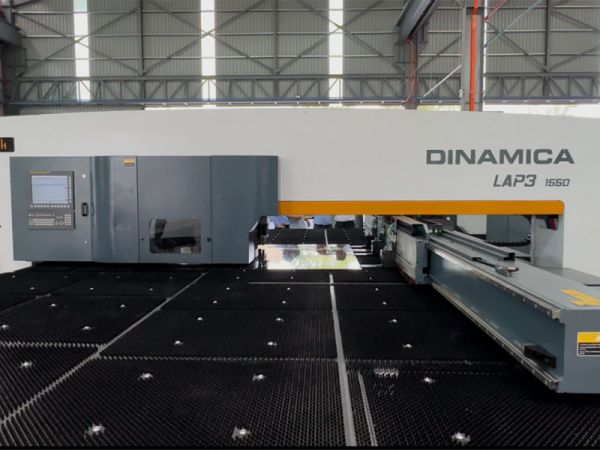

The press brake is equipped with an electro-hydraulic synchronization system, which can achieve higher precision processing and reduce worker labor intensity.

With the use of DERATECH's robotic automatic bending cell, the sheet metal processing operation can be completely automated with only one operator needed for raw material input and finished product transportation. This processing line integrates multiple functions of existing devices, providing significant advantages in terms of equipment quantity investment and operator configuration.